Umgca wokuvelisa udaka olomileyo olulula lweCRM1

Iinkcukacha zeMveliso

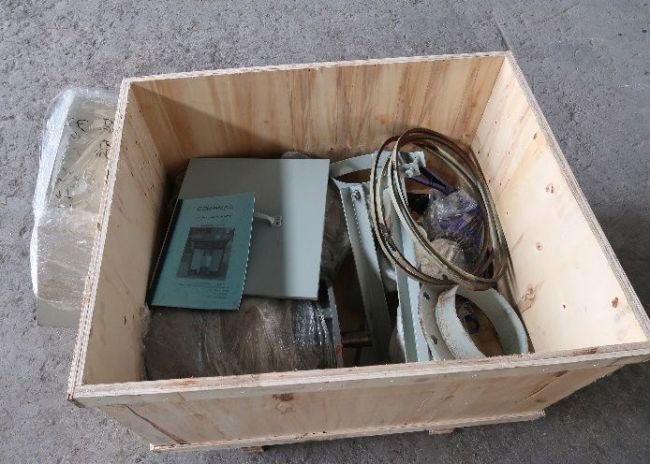

Intshayelelo

Umgca wokuvelisa udaka olomileyo olulula lweCRM1

Umgca wemveliso olula we-CRM1 ufanelekile ukuveliswa kodaka olomileyo, i-putty powder, i-plastering mortar, i-skim coat kunye nezinye iimveliso ze powder.Isethi yonke yezixhobo ilula kwaye iyasebenza, kunye neenyawo ezincinci, utyalo-mali oluphantsi kunye neendleko eziphantsi zokugcinwa.Lukhetho olufanelekileyo kwizityalo ezincinci zokulungisa udaka olomileyo.

Ubumbeko luhamba ngolu hlobo lulandelayo

Screw conveyor

I-Screw conveyor ifanelekile ukuhanjiswa kwezinto ezingabonakaliyo ezifana nomgubo owomileyo, isamente, njl. ihopper yemveliso egqityiweyo.Isiphelo esisezantsi se-screw conveyor esibonelelwe yinkampani yethu sixhotyiswe nge-hopper yokutya, kwaye abasebenzi bafaka izinto eziluhlaza kwi-hopper.I-screw yenziwe nge-alloy steel plate, kwaye ubukhulu buhambelana nezixhobo ezahlukeneyo eziza kuhanjiswa.Zombini iziphelo zeshaft yokuhambisa zisebenzisa isakhiwo esikhethekileyo sokutywina ukunciphisa impembelelo yothuli ekuthwaleni.

Umxubi weribhoni ojikelezayo

I-spiral ribbon mixer inesakhiwo esilula, ukusebenza kakuhle kokuxuba, ukusetyenziswa kwamandla aphantsi, izinga lokuzaliswa komthwalo omkhulu (ngokuqhelekileyo i-40% -70% yomthamo wetanki yomxube), ukusebenza kakuhle kunye nokugcinwa, kwaye ifanelekile ukuxuba izinto ezimbini okanye ezintathu.Ukuze kuphuculwe umphumo wokuxuba kunye nokunciphisa ixesha lokuxuba, senze i-ribbon ye-ribbon ephezulu ye-3;indawo ye-cross-sectional, izithuba kunye nokucoca phakathi kweribhoni kunye ne-mixer tank surface yangaphakathi ziyilwe ngokwezinto ezahlukeneyo.Ukongeza, ngokweemeko ezahlukeneyo zokusebenza, izibuko zokukhupha umxubi zinokuxhotyiswa ngevalve yebhabhathane yezandla okanye ivalve yebhabhathane yepneumatic.

Igqityiwe ihopper yemveliso

I-hopper yemveliso egqityiweyo yi-hopper evaliweyo eyenziwe ngamacwecwe ensimbi ye-alloy yokugcina iimveliso ezixubileyo.Umphezulu we-hopper uxhotyiswe ngechweba lokutya, inkqubo yokuphefumula kunye nesixhobo sokuqokelela uthuli.Inxalenye ye-cone ye-hopper ixhotyiswe nge-vibrator ye-pneumatic kunye nesixhobo sokuqhawula i-arch ukukhusela izinto eziphathekayo kwi-hopper.

Umatshini wokupakisha isikhwama sevalve

Ngokweemfuno zabathengi abahlukeneyo, sinokubonelela ngeentlobo ezintathu ezahlukeneyo zomatshini wokupakisha, uhlobo lwe-impeller, uhlobo lokuvuthuza komoya kunye nohlobo oludadayo lomoya olukhethileyo.Imodyuli yokulinganisa yinxalenye engundoqo yomatshini wokupakisha isikhwama sevalve.Inzwa yokulinganisa, isilawuli sokulinganisa kunye nezixhobo zokulawula i-elektroniki ezisetyenziswe kumatshini wethu wokupakisha zizo zonke iimpawu zodidi lokuqala, ezinoluhlu olukhulu lokulinganisa, ukuchaneka okuphezulu, impendulo ebucayi, kunye nephutha lokulinganisa i-± 0.2%, inokuhlangabezana ngokupheleleyo neemfuno zakho.

Ikhabhinethi yokulawula

Izixhobo ezidweliswe ngasentla kukucwangciswa okusisiseko kolu hlobo lomgca wokuvelisa.Ukuba ufuna ukuqonda umsebenzi wokubethelwa ngokuzenzekelayo kwezinto eziluhlaza, i-batching ene-hopper inokongezwa kumgca wemveliso.Ukuba kufuneka kuncitshiswe uthuli kwindawo yokusebenza kunye nokuphucula indawo yokusebenza yabasebenzi, umqokeleli wothuli omncinci we-pulse unokufakwa.Ngamafutshane, sinokwenza iiprojekthi ezahlukeneyo zoyilo kunye nolungelelwaniso ngokweemfuno zakho.