Ukomisa umgca wemveliso kunye nokusetyenziswa kwamandla aphantsi kunye nemveliso ephezulu

Iinkcukacha zeMveliso

Ukomisa umgca wemveliso

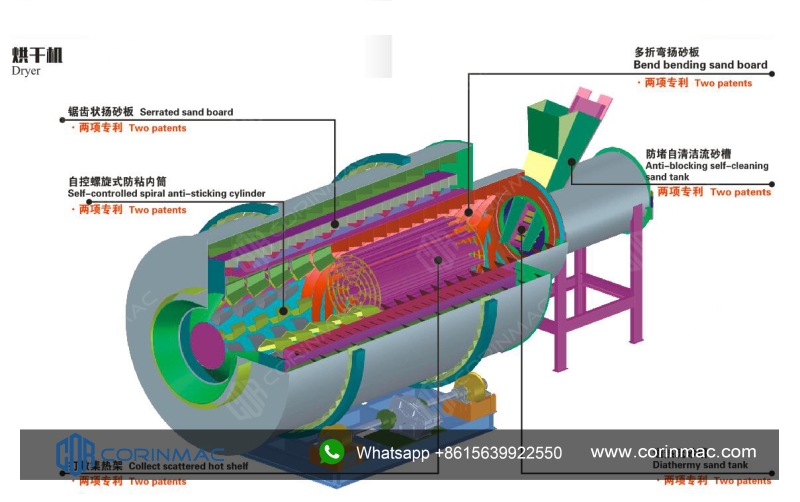

Umgca wemveliso yokumisa isethi epheleleyo yezixhobo zokumisa ukushisa kunye nokuhlola isanti okanye ezinye izinto ezininzi.Iqulathe la malungu alandelayo: ihopper yesanti emanzi, isixhasi sebhanti, isihambisi sebhanti, igumbi elitshisayo, isomisi esijikelezayo (isixhobo esomisa iicylinder ezintathu, isomisi-cylinder enye), inkanyamba, ipulse dust collector, idraft fan, vibrating screen, kunye ne-electronic control system. .

Isanti ityiswa kwihopper yesanti emanzi ngumlayishi, kwaye idluliselwe kwindawo yokungena yesomisi ngebhanti le feeder kunye neconveyor, emva koko ingene kwirotary dryer.I-burner inika umthombo wokushisa owomileyo, kwaye isanti eyomileyo ithunyelwa kwisikrini sokungcangcazela ngumqhubi webhanti ukuze kuhlolwe (ngokuqhelekileyo ubukhulu be-mesh yi-0.63, 1.2 kunye ne-2.0mm, ubungakanani obuthile be-mesh bukhethiweyo kwaye bunqunywe ngokweemfuno zangempela) .Ngexesha lenkqubo yokomisa, i-fan eyidrafti, isitshingitshane, umqokeleli wothuli lwe-pulse kunye nombhobho zenza inkqubo yokususa uthuli yomgca wemveliso, kwaye umgca wonke ucocekile kwaye ucocekile!

Ngenxa yokuba isanti yeyona nto isetyenziswa ngokuqhelekileyo kwimibhobho eyomileyo, umgca wemveliso yokomisa uhlala usetyenziswa kunye nomgca wokuvelisa udaka olomileyo.

Ukuqulunqwa komgca wemveliso

Ihopper yesanti emanzi

Ihopha yesanti emanzi isetyenziselwa ukufumana nokugcina isanti emanzi ukuze yomiswe.Umthamo (umthamo oqhelekileyo yi-5T) unokwenziwa ngokwezifiso ngokweemfuno zomsebenzisi.I-outlet esezantsi kwe-sand hopper idibaniswe kwi-belt feeder.Ulwakhiwo luhlangene kwaye lunengqiqo, lunamandla kwaye luhlala ixesha elide.

Umphakeli webhanti

I-feeder yebhanti zixhobo eziphambili zokondla ngokulinganayo isanti emanzi kwi-dryer, kwaye umphumo wokomisa unokuqinisekiswa kuphela ngokutya izinto ngokulinganayo.I-feeder ixhotyiswe ngesantya esitshintshayo esilawulayo, kwaye isantya sokutya sinokuhlengahlengiswa ngokungekho mthethweni ukufezekisa eyona siphumo sokomisa.Yamkela ibhanti lokuhambisa isiketi ukuthintela ukuvuza kwezinto.

Ukuhambisa ibhanti

Ibhanti yokuhambisa isetyenziselwa ukuthumela isanti emanzi kwisomisi, kunye nokuhambisa isanti eyomileyo kwisikrini esingcangcazelayo okanye nayiphi na indawo echongiweyo.Sisebenzisa ibhanti lokuhambisa inayiloni, elinamandla aphezulu, ukuchasana kwempembelelo kunye nobomi obude.

Igumbi elivuthayo

Ukubonelela indawo yokutshisa amafutha, isiphelo segumbi sinikezelwa nge-inlet yomoya kunye nevalve yokulawula umoya, kwaye ingaphakathi lakhiwe ngesamente ephikisayo kunye nezitena, kwaye ubushushu kwigumbi elivuthayo linokufikelela kwi-1200 ℃.Ubume bayo bugqwesileyo kwaye bunengqiqo, kwaye idibaniswe ngokusondeleyo kunye ne-cylinder yokomisa ukubonelela ngomthombo wobushushu owaneleyo wokomisa.

Iisilinda ezintathu isomisi esijikelezayo

I-3 cylinder rotary dryer iyimveliso esebenzayo kunye neyonga amandla ephuculweyo ngesiseko sesomisi esijikelezayo esisodwa.

Kukho isakhiwo se-drum esinemigangatho emithathu kwi-cylinder, enokwenza izinto zibuyele kathathu kwi-cylinder, ukwenzela ukuba ikwazi ukufumana utshintshiselwano olwaneleyo lokushisa, iphucule kakhulu izinga lokusetyenziswa kobushushu kunye nokunciphisa ukusetyenziswa kwamandla.

Umgaqo wokusebenza

Izinto eziphathekayo zingena kwigubu langaphakathi lesomisi ukusuka kwisixhobo sokutyisa ukuqonda ukomisa ezantsi komlambo.Izinto eziphathekayo ziphakanyiswa ngokuqhubekayo kwaye zisasazwe yipleyiti yokuphakamisa yangaphakathi kwaye ihamba ngendlela ejikelezayo ukuqonda utshintshiselwano lobushushu, ngelixa izinto zihamba zisiya kwelinye isiphelo somgqomo wangaphakathi, kwaye izinto eziqhubekayo ziphakanyiswa ngokuphindaphindiweyo. kwigubu eliphakathi, kwindlela yamanyathelo amabini ukuya phambili kunye nenyathelo elinye ngasemva, izinto ezikwigubu eliphakathi zifunxa ngokupheleleyo ubushushu obukhutshwa ligubu elingaphakathi kwaye zifunxa ubushushu begubu eliphakathi ngaxeshanye, ixesha lokumisa liyandiswa. , kwaye izinto eziphathekayo zifikelela kwimo eyomileyo eyomileyo ngeli xesha.Izinto eziphathekayo zihamba ziye kwelinye icala legubu eliphakathi kwaye emva koko iwela kwigubu elingaphandle.Izinto eziphathekayo zihamba ngendlela ye-rectangular multi-loop kwi-drum yangaphandle.Izinto ezifezekisa umphumo wokomisa ngokukhawuleza zihamba kwaye zikhuphe idrum phantsi kwesenzo somoya oshushu, kwaye izinto ezimanzi ezingakhange zifikelele kwisiphumo sokumisa azikwazi ukuhamba ngokukhawuleza ngenxa yobunzima bawo, kwaye izinto zome ngokupheleleyo kule nqanaba lokuphakamisa uxande. iipleyiti, ngaloo ndlela igqibezela injongo yokomisa.

Iingenelo

1. Isakhiwo se-cylinder emithathu yesigubhu sokumisa sandisa indawo yoqhagamshelwano phakathi kwezinto ezimanzi kunye nomoya oshushu, onciphisa ixesha lokumisa nge-48-80% xa kuthelekiswa nesisombululo sendabuko, kwaye izinga lokunyuka komswakama linokufikelela kwi-120-180 kg. / m3, kwaye ukusetyenziswa kwepetroli kuncitshiswe ngama-48-80%.Ukusetyenziswa yi-6-8 kg / toni.

2. Ukomiswa kwezinto eziphathekayo akwenziwanga kuphela ukuhamba komoya oshushu, kodwa kuqhutywe yi-radiation ye-infrared yensimbi efudumeleyo ngaphakathi, ephucula izinga lokusetyenziswa kobushushu besomisi sonke.

3. Ubungakanani bubonke besomisi buncitshiswe ngaphezu kwe-30% xa kuthelekiswa nezixhobo eziqhelekileyo zokomisa i-cylinder, ngaloo ndlela kuncitshiswa ilahleko yobushushu bangaphandle.

4. Ukusebenza kwe-thermal ye-self-insulating dryer kuphezulu kwi-80% (xa kuthelekiswa ne-35% kuphela kwi-rotary dryer eqhelekileyo), kunye nokusebenza kakuhle kwe-thermal yi-45% ephezulu.

5. Ngenxa yofakelo oludibeneyo, indawo yomgangatho iyancipha nge-50% kwaye iindleko zeziseko zophuhliso ziyancipha nge-60%.

6. Ukushisa kwemveliso egqityiweyo emva kokumisa malunga ne-60-70 degrees, ukwenzela ukuba ayifuni i-cooler eyongezelelweyo yokupholisa.

7. Iqondo lokushisa lokukhupha liphantsi, kwaye ubomi besikhwama sokucoca uthuli lwandiswa ngamaxesha angama-2.

8. Ubumanzi bokugqibela obufunwayo bunokulungelelaniswa lula ngokweemfuno zomsebenzisi.

Iiparamitha zemveliso

| Umzekelo | Isilinda sangaphandle dia.(м) | Ubude besilinda sangaphandle (м) | Isantya esijikelezayo (r/min) | Umthamo (m³) | Umthamo wokomisa (t/h) | Amandla (kw) |

| CRH1520 | 1.5 | 2 | 3-10 | 3.5 | 3-5 | 4 |

| CRH1530 | 1.5 | 3 | 3-10 | 5.3 | 5-8 | 5.5 |

| CRH1840 | 1.8 | 4 | 3-10 | 10.2 | 10-15 | 7.5 |

| CRH1850 | 1.8 | 5 | 3-10 | 12.7 | 15-20 | 5.5*2 |

| CRH2245 | 2.2 | 4.5 | 3-10 | 17 | 20-25 | 7.5*2 |

| CRH2658 | 2.6 | 5.8 | 3-10 | 31 | 25-35 | 5.5*4 |

| CRH3070 | 3 | 7 | 3-10 | 49 | 50-60 | 7.5*4 |

Phawula:

1. Ezi parameters zibalwa ngokusekelwe kumswakama wokuqala wesanti: 10-15%, kwaye umswakama emva kokumisa ungaphantsi kwe-1%..

2. Iqondo lokushisa kwi-inlet ye-dryer yi-650-750 degrees.

3. Ubude kunye nobubanzi bosomisi bunokutshintshwa ngokweemfuno zabathengi.

Impulse uthuli umqokeleli

Sesinye isixhobo sokususa uthuli kumgca wokumisa.Isakhiwo sayo sangaphakathi se-multi-group filter bag kunye noyilo lwejethi ye-pulse inokucoca ngokufanelekileyo kwaye iqokelele uthuli emoyeni ogcwele uthuli, ukwenzela ukuba umxholo wothuli womoya wokukhupha ungaphantsi kwe-50mg / m³, uqinisekisa ukuba uyahlangabezana neemfuno zokusingqongileyo.Ngokweemfuno, sinenqwaba yeemodeli ezifana ne-DMC32, DMC64, DMC112 yokukhetha.

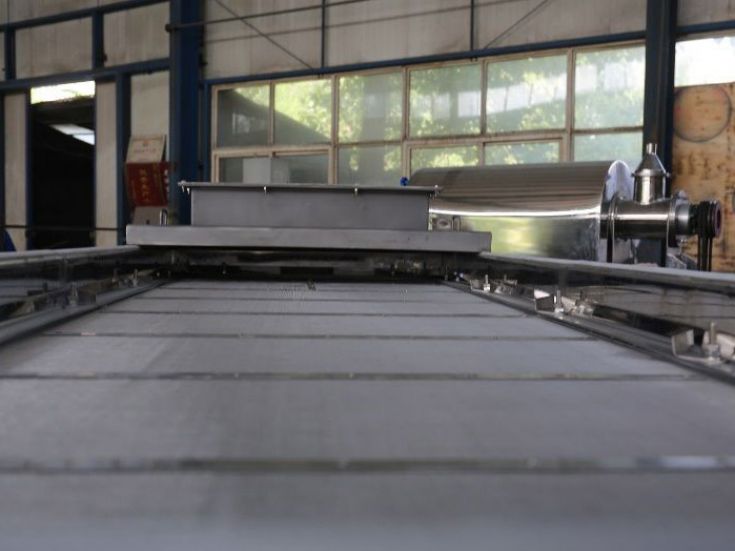

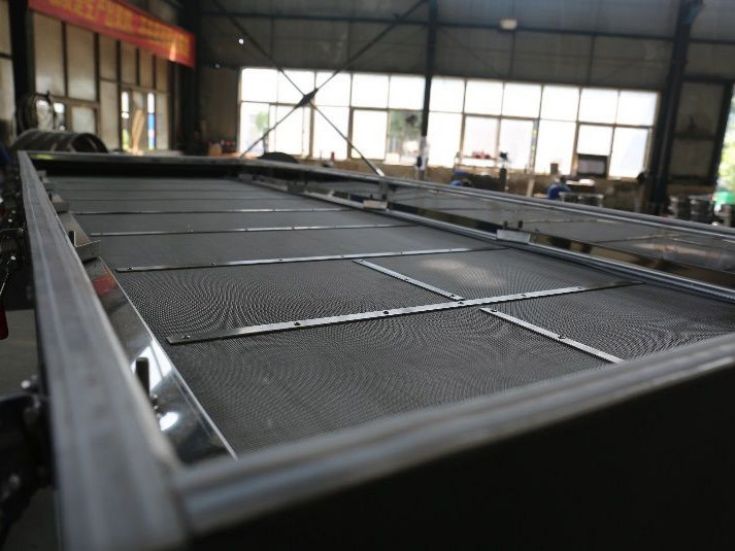

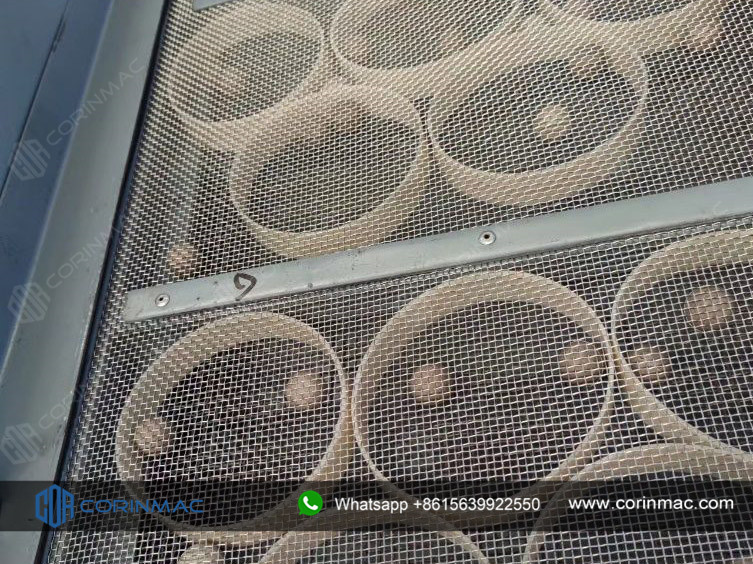

Ukungcangcazela kwesikrini

Emva kokumisa, isanti egqityiweyo (umxholo wamanzi ngokuqhelekileyo ungaphantsi kwe-0.5%) ungena kwisikrini sokungcangcazela, esinokuthi sihlulwe kwiinqununu ezahlukeneyo kwaye zikhutshwe kwii-ports zokukhupha ezichaphazelekayo ngokweemfuno.Ngokuqhelekileyo, ubungakanani be-mesh yesikrini yi-0.63mm, 1.2mm kunye ne-2.0mm, ubungakanani obuthile be-mesh bukhethiwe kwaye bunqunywe ngokweemfuno zangempela.

Zonke isakhelo sentsimbi yesikrini, itekhnoloji yokuqinisa isikrini esisodwa, kulula ukuyitshintsha isikrini.

Iqulathe iibhola zerabha elastiki, ezinokususa ngokuzenzekelayo ukuvaleka kwesikrini

Iimbambo ezininzi zokuqinisa, zomelele ngakumbi kwaye zithembekile

Inkqubo yolawulo yombane

Umgca wemveliso wonke ulawulwa ngendlela edibeneyo, kunye ne-interface yokusebenza ebonakalayo, ngokusebenzisa ukuguqulwa kwamaxesha amaninzi ukulungelelanisa isantya sokutya kunye ne-drum yokomisa ijikeleza, ilawula ngengqondo i-burner, kwaye iqonde ukulawula ukushisa okuhlakaniphile kunye neminye imisebenzi.

Iparameter yobugcisa yokuvelisa imveliso yesanti

| Uluhlu lwezixhobo | Umthamo (Ukufuma kubalwa ngokwe-5-8%) | |||||

| 3-5TPH | 8-10 TPH | 10-15 TPH | 20-25 TPH | 25-30 TPH | 40-50 TPH | |

| Ihopper yesanti emanzi | 5T | 5T | 5T | 10T | 10T | 10T |

| Umphakeli webhanti | PG500 | PG500 | PG500 | Ф500 | Ф500 | Ф500 |

| Ukuhambisa ibhanti | В500х6 | В500х8 | В500х8 | В500х10 | В500х10 | В500х15 |

| Iisilinda ezintathu isomisi esijikelezayo | CRH6205 | CRH6210 | CRH6215 | CRH6220 | CRH6230 | CRH6250 |

| Igumbi elivuthayo | Ukuxhasa (kubandakanya izitena eziqhankqalazayo) | |||||

| Isitshisi (igesi / idizili) Amandla obushushu | RS/RL 44T.C 450-600kw | RS/RL 130T.C 1000-1500 kw | RS/RL 190T.C 1500-2400 kw | RS/RL 250T.C 2500-2800 kw | RS/RL 310T.C 2800-3500 kw | RS/RL 510T.C 4500-5500 kw |

| Imveliso ibhanti yokuhambisa | В500х6 | В500х6 | В500х6 | В500х8 | В500х10 | В500х10 |

| Ukungcangcazela kwesikrini (Khetha isikrini ngokobungakanani besuntswana lemveliso egqityiweyo) | DZS1025 | DZS1230 | DZS1230 | DZS1540 | DZS1230(2台) | DZS1530(2sets) |

| Ukuhambisa ibhanti | В500х6 | В500х6 | В500х6 | В500х6 | В500х6 | В500х6 |

| INkanyamba | Φ500mm | Φ1200 mm | Φ1200 mm | Φ1200 | Φ1400 | Φ1400 |

| Idrafti yefeni | Y5-47-5C (5.5kw) | I-Y5-47-5C (7.5кw) | Y5-48-5C (11kw) | Y5-48-5C (11kw) | Y5-48-6.3C 22кВт | Y5-48-6.3C 22кВт |

| Umqokeleli wothuli lwe-Pulse |

|

|

|

|

| |

Umzobo

Iimveliso zethu

Iimveliso ezicetyiswayo

Iisilinda ezintathu zomiso ezijikelezayo ezinobushushu obuphezulu...

Iimbonakalo:

1. Ubungakanani bubonke bosomisi buncitshiswe ngaphezu kwe-30% xa kuthelekiswa nezixhobo eziqhelekileyo zokomisa iisilinda ezijikelezayo, ngaloo ndlela kuncitshiswa ilahleko yobushushu bangaphandle.

2. Ukusebenza kwe-thermal ye-self-insulating dryer kuphezulu kwi-80% (xa kuthelekiswa ne-35% kuphela kwi-rotary dryer eqhelekileyo), kunye nokusebenza kwe-thermal ku-45% ephezulu.

3. Ngenxa yokufakela i-compact, indawo yomgangatho iyancipha nge-50%, kwaye iindleko zeziseko zophuhliso ziyancipha nge-60%.

4. Ukushisa kwemveliso egqityiweyo emva kokumisa malunga ne-60-70 degrees, ukwenzela ukuba ayifuni i-cooler eyongezelelweyo yokupholisa.

Isomisi esijikelezayo esinokusetyenziswa kwamandla aphantsi kwaye hi...

Iimpawu kunye nezinto eziluncedo:

1. Ngokwezinto ezahlukeneyo zokumisa, isakhiwo esifanelekileyo se-cylinder sinokukhethwa.

2. Ukusebenza okugudileyo nokuthembekileyo.

3. Imithombo eyahlukeneyo yokushisa iyafumaneka: igesi yendalo, idizili, amalahle, amasuntswana e-biomass, njl.

4. Ukulawula ubushushu obukrelekrele.