Isomisi esijikelezayo esinezisilinda ezintathu ezinobushushu obuphezulu

Iinkcukacha zeMveliso

Iisilinda ezintathu isomisi esijikelezayo

I-3-cylinder rotary dryer iyimveliso esebenzayo kunye neyonga amandla ephuculweyo ngesiseko sesomisi esijikelezayo esisodwa.

Kukho isakhiwo se-drum esinemigangatho emithathu kwi-cylinder, enokwenza izinto zibuyele kathathu kwi-cylinder, ukwenzela ukuba ikwazi ukufumana utshintshiselwano olwaneleyo lokushisa, iphucule kakhulu izinga lokusetyenziswa kobushushu kunye nokunciphisa ukusetyenziswa kwamandla.

Umgaqo wokusebenza

Izinto eziphathekayo zingena kwigubu langaphakathi lesomisi ukusuka kwisixhobo sokutyisa ukuqonda ukomisa ezantsi komlambo.Izinto eziphathekayo ziphakanyiswa ngokuqhubekayo kwaye zisasazwe yipleyiti yokuphakamisa yangaphakathi kwaye ihamba ngendlela ejikelezayo ukuqonda utshintshiselwano lobushushu, ngelixa izinto zihamba zisiya kwelinye isiphelo somgqomo wangaphakathi, kwaye izinto eziqhubekayo ziphakanyiswa ngokuphindaphindiweyo. kwigubu eliphakathi, kwindlela yamanyathelo amabini ukuya phambili kunye nenyathelo elinye ngasemva, izinto ezikwigubu eliphakathi zifunxa ngokupheleleyo ubushushu obukhutshwa ligubu elingaphakathi kwaye zifunxa ubushushu begubu eliphakathi ngaxeshanye, ixesha lokumisa liyandiswa. , kwaye izinto eziphathekayo zifikelela kwimo eyomileyo eyomileyo ngeli xesha.Izinto eziphathekayo zihamba ziye kwelinye icala legubu eliphakathi kwaye emva koko iwela kwigubu elingaphandle.Izinto eziphathekayo zihamba ngendlela ye-rectangular multi-loop kwi-drum yangaphandle.Izinto ezifezekisa umphumo wokomisa ngokukhawuleza zihamba kwaye zikhuphe idrum phantsi kwesenzo somoya oshushu, kwaye izinto ezimanzi ezingakhange zifikelele kwisiphumo sokumisa azikwazi ukuhamba ngokukhawuleza ngenxa yobunzima bawo, kwaye izinto zome ngokupheleleyo kule nqanaba lokuphakamisa uxande. iipleyiti, ngaloo ndlela igqibezela injongo yokomisa.

Iingenelo

1. Isakhiwo se-cylinder emithathu yesigubhu sokumisa sandisa indawo yoqhagamshelwano phakathi kwezinto ezimanzi kunye nomoya oshushu, onciphisa ixesha lokumisa nge-48-80% xa kuthelekiswa nesisombululo sendabuko, kwaye izinga lokunyuka komswakama linokufikelela kwi-120-180 kg. / m3, kwaye ukusetyenziswa kwepetroli kuncitshiswe ngama-48-80%.Ukusetyenziswa yi-6-8 kg / toni.

2. Ukomiswa kwezinto eziphathekayo akwenziwanga kuphela ukuhamba komoya oshushu, kodwa kuqhutywe yi-radiation ye-infrared yensimbi efudumeleyo ngaphakathi, ephucula izinga lokusetyenziswa kobushushu besomisi sonke.

3. Ubungakanani bubonke besomisi buncitshiswe ngaphezu kwe-30% xa kuthelekiswa nezixhobo eziqhelekileyo zokomisa i-cylinder, ngaloo ndlela kuncitshiswa ilahleko yobushushu bangaphandle.

4. Ukusebenza kwe-thermal ye-self-insulating dryer kuphezulu kwi-80% (xa kuthelekiswa ne-35% kuphela kwi-rotary dryer eqhelekileyo), kunye nokusebenza kakuhle kwe-thermal yi-45% ephezulu.

5. Ngenxa yofakelo oludibeneyo, indawo yomgangatho iyancipha nge-50% kwaye iindleko zeziseko zophuhliso ziyancipha nge-60%.

6. Ukushisa kwemveliso egqityiweyo emva kokumisa malunga ne-60-70 degrees, ukwenzela ukuba ayifuni i-cooler eyongezelelweyo yokupholisa.

7. Iqondo lokushisa lokukhupha liphantsi, kwaye ubomi besikhwama sokucoca uthuli lwandiswa ngamaxesha angama-2.

8. Ubumanzi bokugqibela obufunwayo bunokulungelelaniswa lula ngokweemfuno zomsebenzisi.

Iiparamitha zemveliso

| Umzekelo | Isilinda sangaphandle dia.(м) | Ubude besilinda sangaphandle (м) | Isantya esijikelezayo (r/min) | Umthamo (m³) | Umthamo wokomisa (t/h) | Amandla (kw) |

| CRH1520 | 1.5 | 2 | 3-10 | 3.5 | 3-5 | 4 |

| CRH1530 | 1.5 | 3 | 3-10 | 5.3 | 5-8 | 5.5 |

| CRH1840 | 1.8 | 4 | 3-10 | 10.2 | 10-15 | 7.5 |

| CRH1850 | 1.8 | 5 | 3-10 | 12.7 | 15-20 | 5.5*2 |

| CRH2245 | 2.2 | 4.5 | 3-10 | 17 | 20-25 | 7.5*2 |

| CRH2658 | 2.6 | 5.8 | 3-10 | 31 | 25-35 | 5.5*4 |

| CRH3070 | 3 | 7 | 3-10 | 49 | 50-60 | 7.5*4 |

Phawula:

1. Ezi parameters zibalwa ngokusekelwe kumswakama wokuqala wesanti: 10-15%, kwaye umswakama emva kokumisa ungaphantsi kwe-1%..

2. Iqondo lokushisa kwi-inlet ye-dryer yi-650-750 degrees.

3. Ubude kunye nobubanzi bosomisi bunokutshintshwa ngokweemfuno zabathengi.

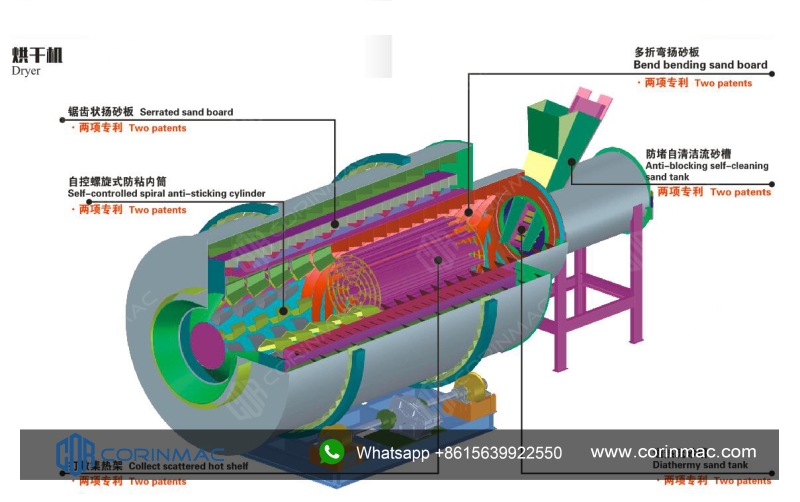

Umzobo

Iimveliso zethu

Iimveliso ezicetyiswayo

Isomisi esijikelezayo esinokusetyenziswa kwamandla aphantsi kwaye hi...

Iimpawu kunye nezinto eziluncedo:

1. Ngokwezinto ezahlukeneyo zokumisa, isakhiwo esifanelekileyo se-cylinder sinokukhethwa.

2. Ukusebenza okugudileyo nokuthembekileyo.

3. Imithombo eyahlukeneyo yokushisa iyafumaneka: igesi yendalo, idizili, amalahle, amasuntswana e-biomass, njl.

4. Ukulawula ubushushu obukrelekrele.

Ukomisa umgca wemveliso kunye nokusetyenziswa kwamandla aphantsi ...

Iimpawu kunye nezinto eziluncedo:

1. Umgca wemveliso wonke ufumana ulawulo oludibeneyo kunye nojongano lokusebenza olubonakalayo.

2. Lungisa isantya sokutya kwezinto kunye nesantya esijikelezayo esomisi ngokuguqulwa kwamaza.

3. Ulawulo olukrelekrele lokutshisa, umsebenzi wokulawula ubushushu obukrelekrele.

4. Ubushushu bezinto ezomileyo ziyi-60-70 degrees, kwaye zingasetyenziswa ngokuthe ngqo ngaphandle kokupholisa.